Precision Rifle Barrels and Custom Chambering Services

At Rachel Precision, creating the perfect rifle starts with a precision-crafted barrel and expert chambering. These two components work hand in hand to deliver the accuracy and consistency that serious shooters rely on. Here’s a look at the meticulous services we use to ensure every barrel and chamber we produce is tailored to perform at the highest level.

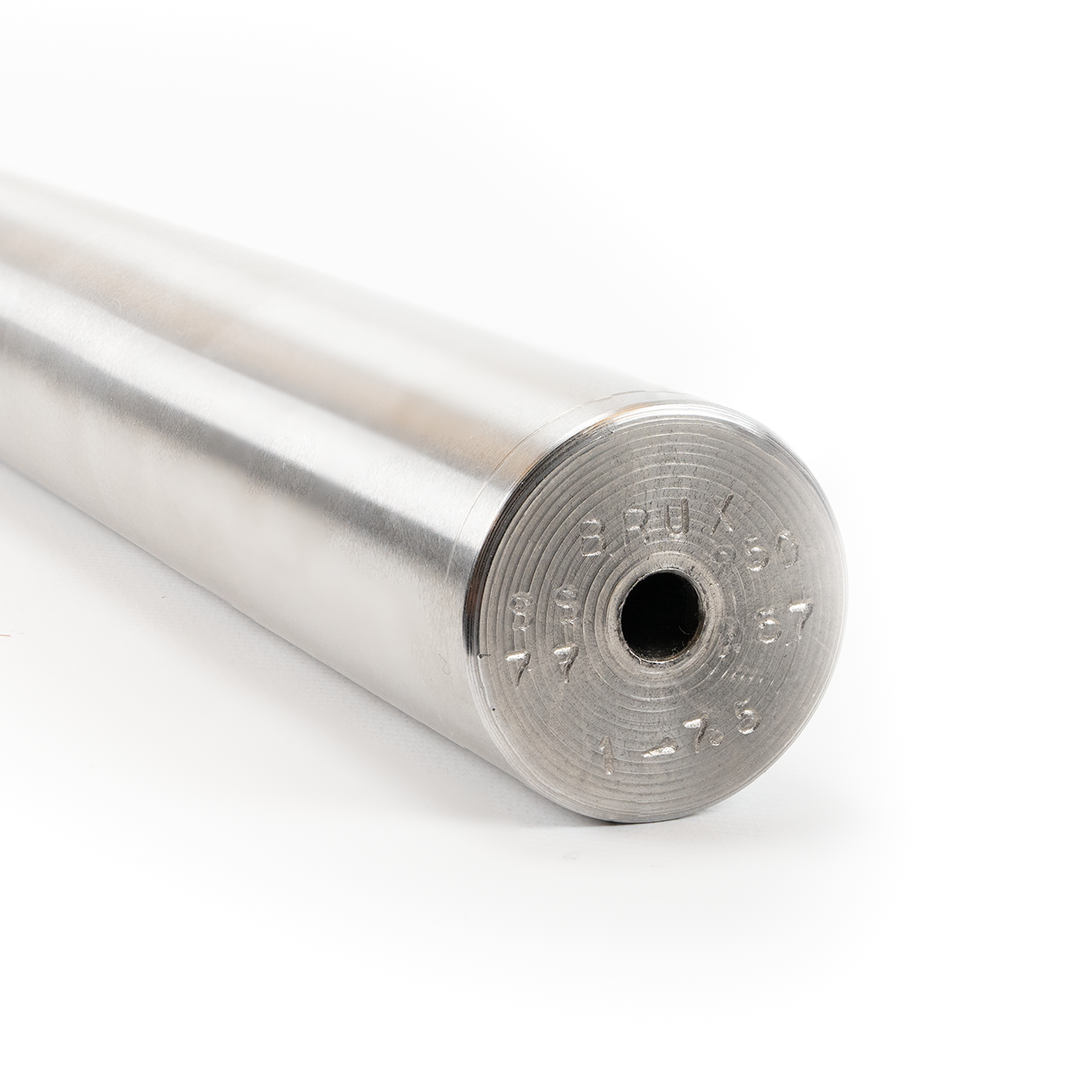

Barrel Blank Selection

The foundation of every custom rifle starts with choosing the right barrel blank. We only work with top-tier manufacturers like Brux, CRB, Krieger, Bartlein, Benchmark, and Muller Works whos barrels are known for their consistency, quality, and precision. The selection of barrel blank material—typically high-grade stainless steel—is critical for durability, heat resistance, and longevity. We work with each client to select the best caliber, barrel length, and contour that matches their shooting goals, whether for long-range precision or hunting applications.

Barrel Rifling

Rifling is a critical part of the barrel-building process and plays a significant role in determining a rifle’s accuracy. The rifling consists of spiral grooves cut inside the barrel that cause the bullet to spin as it exits. This spinning stabilizes the bullet in flight, ensuring it stays on track and hits the target with precision. The method used to create the rifling can greatly influence the bullet’s flight path and overall performance, which is why trusting expert barrel makers is essential for achieving the highest level of accuracy.

At Rachel Precision, we offer custom twist rates based on the caliber and type of ammunition you plan to use. By matching the twist rate to your specific shooting needs, we ensure your bullets remain stable and accurate, especially at long distances. Whether using button or cut rifling, our meticulous attention to detail guarantees the highest level of accuracy and consistency in every rifle barrel we craft.

Types of Rifling

At Rachel Precision, we use two of the most respected rifling methods: button rifling and cut rifling.

- Button Rifling: This process involves pulling or pushing a hard button through the barrel, creating the rifling grooves by displacing metal. Button rifling is a quicker process that provides excellent accuracy and is widely used for precision shooting applications. It offers a smooth finish and uniform grooves, making it ideal for a variety of calibers.

- Cut Rifling: This traditional method involves cutting the rifling grooves one at a time using a precision tool. Cut rifling is known for its ability to produce deeper and more uniform grooves, and it allows for greater flexibility in custom twist rates. This method is often favored for its consistency and ability to maintain high performance over a long lifespan, especially in heavy-duty barrels.

Chambering

Chambering is one of the most critical services we provide at Rachel Precision, as it directly affects the accuracy, reliability, and performance of your rifle. The chamber is where the cartridge is seated before firing, and it must be cut with absolute precision to guarantee the proper fit and function. Even the slightest imperfection in chamber dimensions can lead to issues like inconsistent pressure, poor accuracy, or even dangerous malfunctions.

We use specialized, high-precision reamers to cut each chamber to exact specifications, ensuring that every chamber we create is a perfect match for your ammunition. Our custom chambering process guarantees a precise, snug fit, which is essential for maintaining optimal pressure levels when the round is fired. This level of precision in machining results in more consistent velocities, improved accuracy, and greater reliability with every shot.

By focusing on these minute details, we ensure that each chamber is machined to exacting standards, providing the consistency and performance necessary for precision shooting. In the world of precision rifles, where even fractions of a millimeter matter, our expert chambering process delivers the accuracy and reliability you need to perform at your best.

True Bore Alignment system

To further enhance precision, we utilize our True Bore Alignment system, a critical component in our chambering process that ensures the chamber is perfectly centered and aligned with the bore. This system works by carefully aligning the chamber with the exact centerline of the bore, eliminating any potential offset or misalignment that could negatively impact the performance of the rifle.

By using True Bore Alignment, we can ensure that both the barrel and the chamber are precisely concentric, allowing for optimal bullet travel and reducing the chance of inconsistencies in shot placement. This method also minimizes the potential for uneven pressure distribution inside the chamber, which can cause wear on components and decrease the lifespan of the rifle.

The result is a smoother, more efficient chambering process that not only improves accuracy but also enhances overall consistency. Whether for long-range shooting or competitive environments, this precision translates into tighter groupings, better ballistic performance, and greater reliability shot after shot. The True Bore Alignment system is an essential part of how we maintain the highest standards of craftsmanship at Rachel Precision.

Crowning

The crown is the very end of the barrel where the bullet exits. A properly cut crown is essential for maintaining accuracy because any imperfection here can disrupt the bullet’s flight path. We offer precision crowning services that ensure the gases exit uniformly around the bullet, allowing it to maintain a straight trajectory. A well-done crown enhances the overall accuracy and consistency of your rifle.

Barrel Bedding

Finally, to ensure stability, the barrel is bedded to the stock using precision glass bedding. This process eliminates any movement between the action and the stock, ensuring that the barrel remains steady even under recoil. Proper bedding enhances accuracy, as it prevents the barrel from shifting, which could cause inconsistent shot placement.

What Sets Us Apart?

All of our turning centers are equipped with back flush coolant systems, which play a crucial role in maintaining both cleanliness and precision during the chambering process. These setups continuously flush coolant through the chamber, effectively removing chips and debris that can accumulate during machining. By keeping the chamber clear of obstructions, we minimize the risk of imperfections or scoring on the critical surfaces of the chamber and barrel. This ensures that each chambering operation is conducted with maximum precision, delivering a flawless, stress-free fit for the cartridge, while also extending the life of the tools and improving overall machining efficiency.